metal porous powder stintering filter cartridge

metal powder sintered filter cartridge for liquid filtration under high temperature&temperature condition.

Sintered metal powder filter cartridges are constructed from fine-woven stainless steel powder which is sintered at each wire contact point in a process to produce an extremely strong surface-sieving porous material with extremely narrow pore size distribution. Unlike unsintered meshes, filter media will not shift under stress. Sintering also enables the use of finer wires to produce more pores per unit area for higher flow rates and higher contaminant loading capacity

Features and Benefits

All-stainless steel construction

Sintered mesh screen media

Pleated for high-capacity

Consistent and fixed pore size

Corrosion resistant

High pressure resistant

Withstands high reverse-flows

High-temperature capabilities

Repeatedly cleanable

No soluble polymeric extractables

No unloading or shedding

Absolute rated for reliable performance

ISO 9000 Certified Quality System

Manufactured for use in conformance with cGMP

FDA-listed materials per 21 CFR

Materials of Construction

Medium: 304 L stainless steel

Core and End Caps: 304 stainless steel

Gaskets: Buna-N

Nominal Dimensions

Diameters: 64 mm (2.5 in.)

Operating Conditions

Maximum Differential Pressure and Temperature

Forward Flow Direction: 8.6 bard (125 psid) to 232 °C (450 °F)

Reverse Flow Direction: 0.7 bard (10 psid) to 232 °C (450 °F)

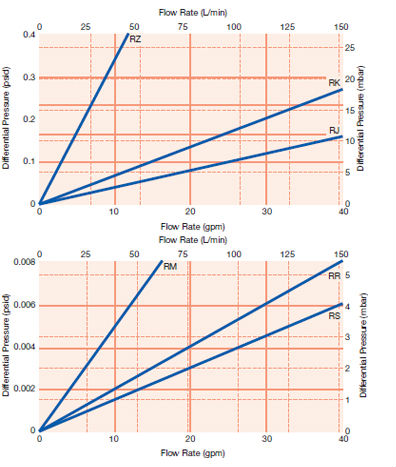

| Grade | Aqueous L/min (gal/min) | Air Nm3/hr (acfm) |

| RA | 14 (3.7) | 47 (300) |

| RT | 11 (2.9) | 38 (240) |

| RS | 8.8 (2.3) | 32 (200) |

| RR | 7.0(1.8) | 24 (150) |

| RM | 3.3 (0.8) | 16 (100) |

| RJ | 3.5 (0.9) | 13 (80) |

| RK | 2.8(0.7) | 11 (69) |

| RZ | 1.8 (0.5) | 6.3 (40) |

Typical Liquid Flow Rate