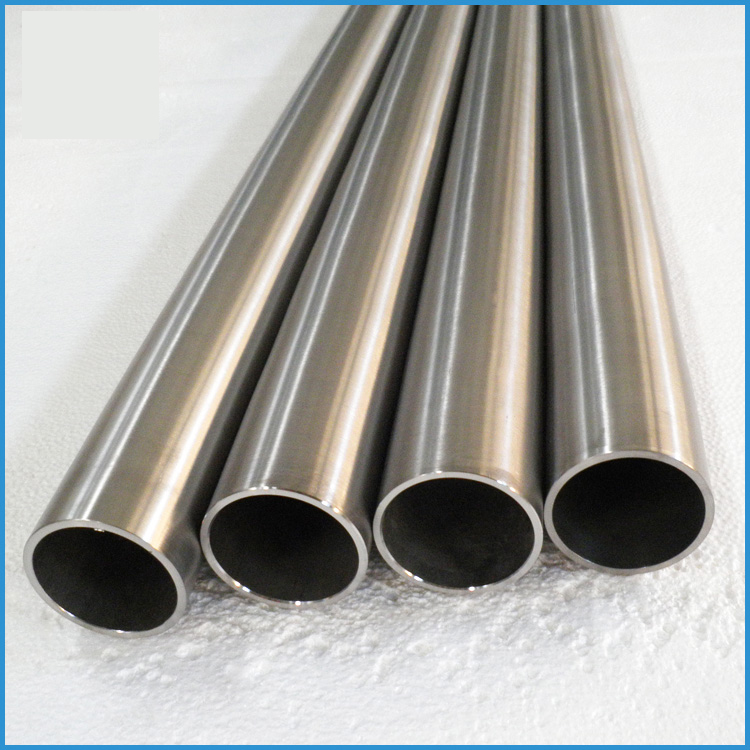

Seamless Titanium Pipe & Tube

titanium seamless tube and pipe

titanium seamless tube and pipe

1.Standard: ASTM B338, ASTM B337, ASTM B861

2.Metrial:Gr.1 Gr.2 Gr.3 Gr.7 Gr.9 Gr.11 Gr.12 GR.23

3.. Dimension: OD.(8-120)*Th.(0.5-10)*Length<6000mm

4. Condition: Extruding and Rolling

5. Surface treatment: polish, acid cleaning

6.Chemical and Tensile

|

|

N |

C |

H |

Fe |

0 |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

bal |

|

GR5eli |

0.03 |

0.08 |

0.012 |

0.25 |

0.13 |

5.5~6.5 |

3.5~4.5 |

|

|

|

|

|

Grade |

Tensile strength(min) |

Yeild strength(min) |

Elongation(%) |

||

|

ksi |

MPa |

Ksi |

MPa |

||

|

1 |

35 |

240 |

20 |

138 |

24 |

|

2 |

50 |

345 |

40 |

275 |

20 |

|

3 |

65 |

450 |

55 |

380 |

18 |

|

4 |

80 |

550 |

70 |

483 |

15 |

|

5 |

130 |

895 |

120 |

828 |

10 |

|

7 |

50 |

345 |

40 |

275 |

20 |

|

9 |

90 |

620 |

70 |

438 |

15 |

|

12 |

70 |

438 |

50 |

345 |

18 |

|

23 |

860 |

795 |

825 |

760 |

8 |

7.Production flow

Titanium sponge→ Voltage→ Melting → Titanium ingots→ Forging → Plate billet→ Hot rolled → Titanium belt → Welding → Welding tube titanium sponge→ Voltage→ Melting→ Titanium ingots→ Forging →Bar bilet→ Extrusion→ Rolling→ Straightening →Seamless tube

8.application:

1. Oceaneering: evaporator, heat transmitter, exchanger,oil production platform, oil cooler, running pipe etd.

2. Thermal power engineering:condenser, heat exchanger, engine vane etd

3. Chemical engineering:Flat plate heat exchanger, flat plate condenser, cooler tower,chloride barrels etd