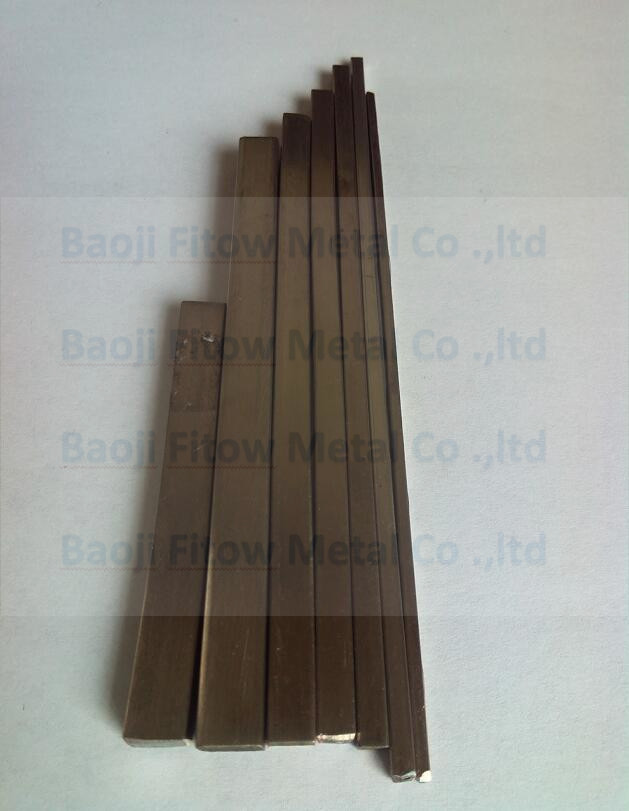

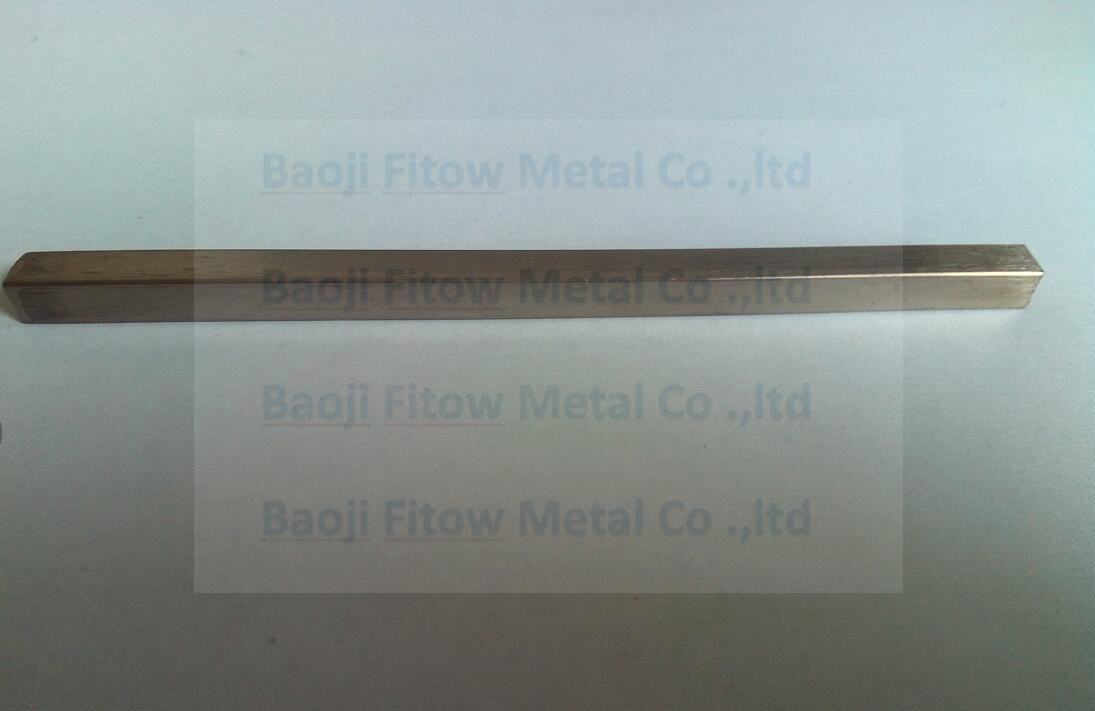

ASTM B348 Titanium Flat Bar / Rod

titanium bar, titanium square bar, titanium flat bar

Process Flow:

Titanium sponge→Compacting electrodes→Melting→Forging→Billets→Hot rolled

→Annealing →Machining or pickling →Bars

| Titanium flat bar | Process Flow | Size |

| Titanium flat bar | Hot rolled | 8mm×8mm×L 9mm×9mm×L |

| Titanium flat bar | 10mm×10mm×L 11mm×11mm×L | |

| Titanium flat bar | 12mm×12mm×L 12.7mm×12.7mm×L | |

| Titanium flat bar | 6.35mm × 12.7mm × L 12.7mm×25.4mm×L | |

| Titanium flat bar | forged | other size can custom-made according to requiry |

The density of titanium is 4.506-4.516g/cm^3, melting point is 1668, boiling point is 3535. In the appropriate oxidizing environment also has excellent corrosion resistance. Therefore, 产品展示 are widely used in aerospace structural materials, such as aircraft, rockets, missiles and spacecraft, ship manufacture, chemical industry, conventional weapons, manufacturing, metallurgical industry, health care, ultra-high vacauum and other fields.

| Element | Composition,% | |||||||||

| Grade1 | Grade2 | Grade3 | Grade4 | Grade5 | Grade6 | Grade7 | Grade9 | Grade11 | Grade12 | |

| N max | 0.03 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| C max | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| H max | 0.05 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| Fe max | 0.2 | 0.3 | 0.3 | 0.5 | 0.4 | 0.3 | 0.5 | 0.25 | 0.2 | 0.3 |

| O max | 0.18 | 0.25 | 0.35 | 0.4 | 0.2 | 0.2 | 0.25 | 0.15 | 0.18 | 0.25 |

| Al | 5.5-6.75 | 4.0-4.6 | 2.5-3.5 | |||||||

| V | 3.5-4.5 | 2.0-3.0 | ||||||||